Çelik ile Geleceğe Şekil Veriyoruz.

Çelik ile Geleceğe Şekil Veriyoruz.

İstanbul’da kurulan firmamız, yüksek karbonlu yaylık çelik ve paslanmaz yaylık çelik sektöründeki faaliyetlerine 1976 yılında başlamıştır. Beylikdüzü/İstanbul’daki 6700m² Çelik Servis Merkezi, Orhangazi/Bursa’daki 4700m² Üretim Tesisi ve Zeytinburnu/İstanbul’daki Merkez Ofisi ile Türkiye geneline hizmet vermektedir.

- Deneyim, Üretim, İhracat

TECRÜBE

ÜRETİM ALANI

İHRACAT

Sürdürülebilir Üretim ile Geleceği Çelik ile Şekillendiriyoruz.

Sürdürülebilir Üretim ile Geleceği Çelik ile Şekillendiriyoruz.

Sürdürülebilir üretim ve geleceğe katkı yapacak inovasyonlar için çalışıyoruz. Ürünlerimizi kullanan herkes aynı zamanda geleceğe katkı sağladığını biliyor.

Fuarlarımız

Fuarlarımız

UK Metal EXPO 2024

Yakında UK Metal EXPO 2024’te sizlerle buluşmak için sabırsızlanıyoruz.

ADVANCED MANUFACTURING METAL MADRID 2024

20 Kasım, 2024 – 21 Kasım, 2024’de sizleri bekliyoruz.

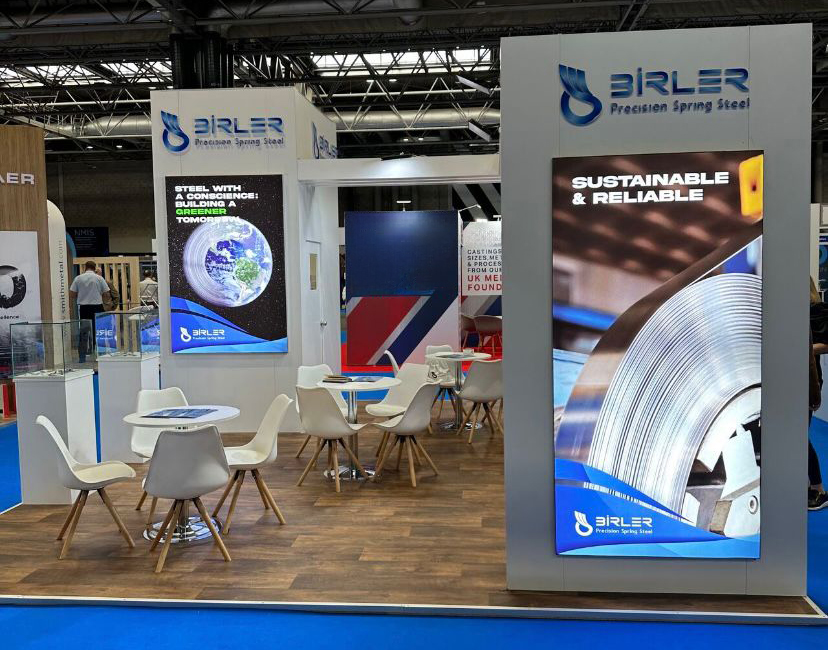

UK Metal EXPO 2023

UK Metal EXPO 2023’te bizi ziyaret eden herkese teşekkür ederiz.

Kariyer

Kariyer

Geleceğe beraber emin adımlarla yürüyoruz. Çünkü birbirimize güveniyoruz.

Geleceğe beraber emin adımlarla yürüyoruz. Çünkü birbirimize güveniyoruz.

En büyük değerin insandan geldiği bilinci ile sizin kariyerinize önem veriyor bunun için sürekli gelişim ilkesi ile çalışıyoruz.

Birler Çelik ailesinin bir parçası olmak için, açık pozisyonlar sayfasını inceleyerek kendinize kariyer hedeflerinize uygun bir pozisyon bulabilir, veya genel başvuru aracılığı ile

Zaman içerisinde açılacak pozisyonlar için kendinizi bize tanıtmış olabilirsiniz.

Ayrıca en genç arkadaşlarımıza özellikle önem veriyoruz. Her yıl gerçek bir iş hayatına giriş süreci yaşamak isteyen gençler ile stajyer programlarımız ile geleceğe hazırlık yapıyoruz.